Dry Air Generator Uses:

Dry air generator is widely used to supply dry air to large power equipment such as transformer and reactor during overhaul. The dry air provided ensures that the internal insulation of power equipment is not damp and that the maintenance personnel will not asphyxiate due to lack of oxygen when working inside the equipment. It is safer, more reliable, more economical and more convenient than using nitrogen. When using dry air generator for equipment maintenance, it can not be affected by the changes of external climate conditions, especially overnight operation. It only needs to seal flanges everywhere and fill dry air with 0.1-0.3 Mpa, without oil injection, transformers, reactors and so on will not be damp. It reduces the workload of pumping and injecting oil every day, shortens the overhaul period and improves the quality of overhaul. In the process of oil filtering, the tank body and oil can be air-filled and dried. When oil is filtered in rainy days and humid environment, it can ensure the improvement of oil insulation and the decrease of water content. After the oil depot (oil tank) is connected with the dry gas engine, the reserve oil in stock can be guaranteed to be in a qualified state for a long time, so as to be ready for use at any time in the surprise project. It can also be used in other warehouses, libraries and production sites which need some dry air.

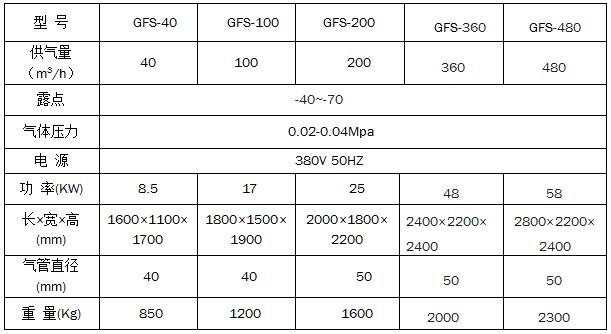

Technical parameters table: